Strict controls allow us to improve our sustainability performance every year thanks to the dedication of the entire team working in the Company.

Strict controls allow us to improve our sustainability performance every year thanks to the dedication of the entire team working in the Company.

*scm= standard cubic metre

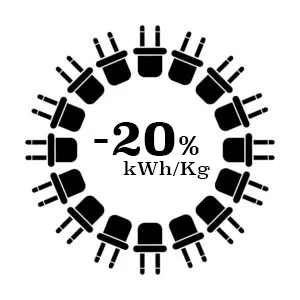

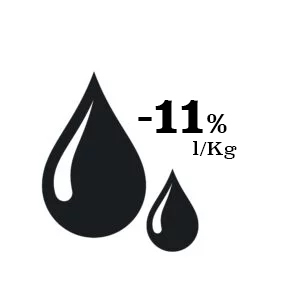

The values indicated were obtained thanks to the consolidation of actions and investments – made in the period 2015-2023- aimed at improving the efficiency of the production process