Strict controls allow us to improve our sustainability performance every year thanks to the dedication of the entire team working in the Company.

Strict controls allow us to improve our sustainability performance every year thanks to the dedication of the entire team working in the Company.

*scm= standard cubic metre

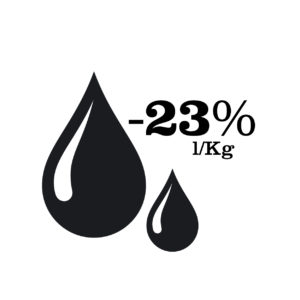

The values indicated were achieved thanks to the consolidation of investments in the production process carried out in the five-year period 2016-2021

When reading the figures, the 46% increase in kg of textiles produced from 2016 to 2021 should be taken into account